|

|||||

|

|

|||||

|

|||||

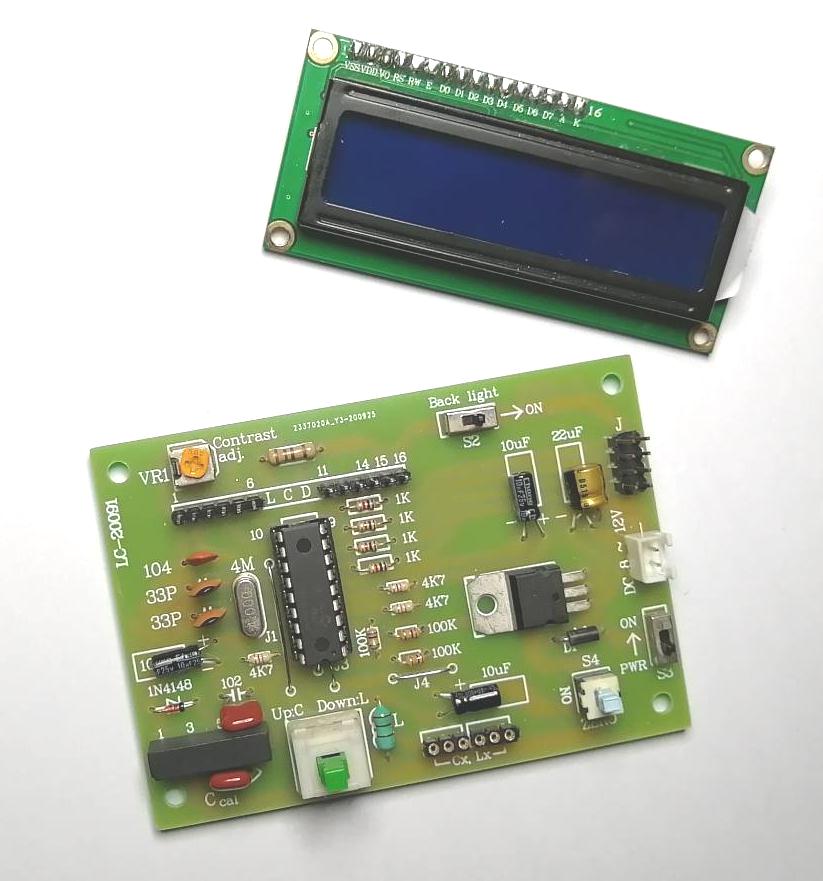

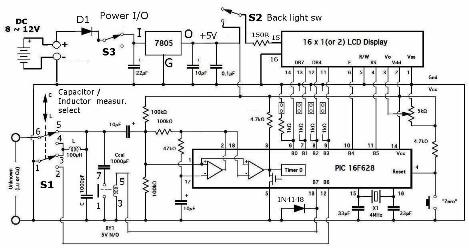

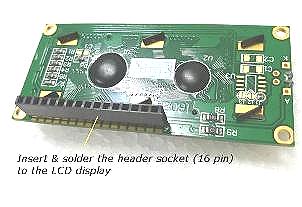

CONSTRUCTION |

|||||

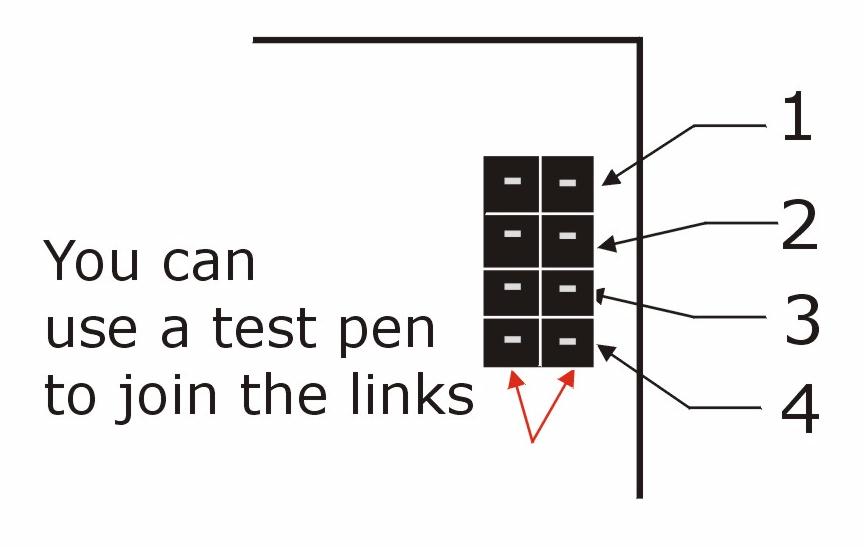

TEST & CALIBRATION (needs to be done only once) |

|||||

|

|

|||||

** Please refer to Phil Rice's Home Page. for a full description of calibration procedure under the title " Calibration Instructions " |

|||||

|

HOW TO USE |

|||||

|

CAPACITANCE MEASUREMENT :

1 Set the mode switch (S1) to "up" position 2. Switch on the

meter (S3) & let the meter initialize (the reading may not be

zero).

INDUCTANCE

MEASUREMENT :

1 Set the mode switch (S1) to "up" position as in the case of capacitance measurement 2. Switch on the

meter (S3) & let the meter initialize (the reading may not be

zero). 3.

Now set the mode switch (S1) to "down" position for inductance

measurement |

|||||

PARTS LIST |

|||||

|

.jpg)

.jpg)